VMC850B CNC Milling mochini, paatsepama mochini setsi

Likarolo tsa Sehlahisoa

1.Taelo e akaretsang

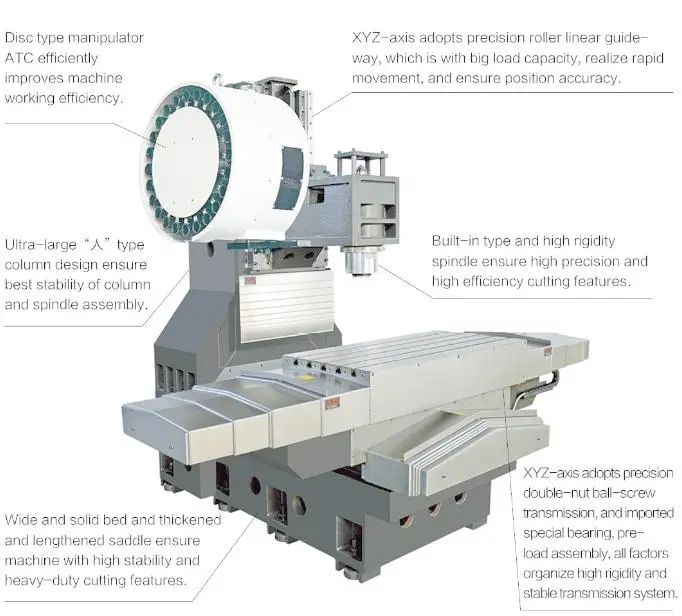

Mochine ona o entsoe ka sebopeho sa foreimi e otlolohileng. Kholomo e behiloe holim'a 'mele oa mochini, lebokose la spindle le thella kholomong e etsang motsamao oa axis oa Z, li-slide tse holim'a' mele oa mochini li etsa motsamao oa Y axis, li-slide tse sebetsang holim'a saddle ho etsa motsamao oa X axis. Lilepe tse tharo kaofela ke litselana tse tsamaeang ka lebelo le holimo le ho nepahala ho holimo. Re sebelisa tšepe ea boleng bo holimo ea boleng bo holimo bakeng sa 'mele oa mochini, kholomo, saddle, tafole ea ho sebetsa, lebokose la spindle le nang le theknoloji ea lehlabathe la resin le kalafo ea botsofali ea makhetlo a 2 ho felisa khatello ea kahare e setseng ea thepa. Likarolo tsena kaofela li ntlafalitsoe ke software ea SolidWorks, e ntlafatsang ho tiea le botsitso eseng feela bakeng sa likarolo tsena empa le mochini. Hape e tla thibela deformation le vibration e bakoang ke ho itšeha. Likarolo tsa bohlokoa kaofela li romelloa ho tsoa ho brand e tummeng ea lefats'e ho etsa mochini o nang le botsitso bo phahameng le ho tšoarella. Mochini ona o ka fihlella ts'ebetso ea ho sila, ho cheka, ho tsosolosa, ho bora, ho tsosolosa, ho tlanya, 'me hangata e sebelisoa bakeng sa Masole, merafo, likoloi, hlobo, lisebelisoa le liindasteri tse ling tsa ho lokisa mechine. E ka sebelisoa bakeng sa mefuta eohle ea ho nepahala ho phahameng le mefuta e mengata ea ts'ebetso. E ntle bakeng sa tlhahiso e nyane le e mahareng, e nang le mefuta e mengata, hape e ka kenya mohala oa tlhahiso ea othomathike.

2.Three lilepe tsamaiso

Lilepe tse tharo kaofela li na le litselana 'me li na le moralo o moholo oa span bakeng sa ho nepahala ho tšoarellang. Li-motors tsa lilepe tse 3 li hokahane ka kotloloho le sekoti sa bolo e nepahetseng ka ho fetesisa ka ho se kopane ha lekhalo. Sekorufu se seng le se seng sa lilepe tse 3 se romelloa ka ntle ho tsoa ho sekoti se nepahetseng sa angular le li-bearings tsa profeshenale tse tsamaellanang, hape re tla etsa pre-tension bakeng sa li-ball screws bakeng sa ho nepahala le ho nepahala ho holimo. The Z-axis servo motor e na le tšebetso ea brake ea othomathike. Tabeng ea ho felloa ke matla, brake ea enjene e ka ts'oaroa ke brake ka bo eona ho e thibela ho potoloha, e phethang karolo ea ts'ireletso ea polokeho.

3.Spindle unit

Spindle e hlahisoa ke moetsi oa litsebi ho etsa bonnete ba ho nepahala le ho tiea. Spindle bearing e tsoa ho mofuta o tummeng oa lefatše o nang le boleng bo holimo, 'me o bokelloa maemong a mocheso o sa feleng mme ha ho lerōle. Ka mor'a moo, li-spindles tsohle li tla etsa teko ea ho leka-lekanya matla ho etsa bonnete ba hore nako ea bophelo le ho tšepahala. E na le tsamaiso e tlaase ea khatello ea moea, e butsoelang moea o tlaase sebakeng se ka hare sa spindle ho etsa lesela la tšireletso ea moea ho thibela lerōle, le phodileng. seluloana. Bakeng sa boemo bona, seluloana sa spindle se tla sebetsa tlas'a tikoloho e se nang tšilafalo, e tla sireletsa yuniti ea spindle le nako e telele ea bophelo ba ho ohla. Lebelo la spindle e ka se be -mohato o fetotsoe ka har'a lebelo la lebelo la spindle, le laoloang ke encode e ka hare ea enjene hore e be le ts'ebetso ea ho tjeka ha spindle le ho tlanya ka thata.

4.Thulusi ea ho fetola tsamaiso

Bokhoni ba makasine ea lisebelisoa tse tloaelehileng tsa mochini ona ke 24T mme bo bokane ka kholomong ea lehlakore. Ha e fetola sesebelisoa, sesebelisoa sa poleiti ea lisebelisoa 'me e behiloe ka mochine oa mochine oa koloi, ka mor'a hore spindle e fihle boemong ba phetoho ea sesebelisoa, ATC e tla finyella phetoho ea sesebelisoa le ho romela ketso ea sesebelisoa. ATC ke mochine oa hobbing cam 'me o etsa hore ho be le tsitsipano pele ho nako e ka potoloha ka lebelo le phahameng, ho leng molemo ho fetola sesebelisoa ka potlako le ka nepo.

5.Sistimi e phodileng

Mochini o na le pompo e kholo ea ho qoelisa e otlolohileng le tanka e kholo ea metsi. Lebelo la pompo e pholileng ke 2m³/h ho etsa bonnete ba hore ho na le pholile e lekaneng ea ho sebelisa hape. Ho na le nozzle e pholileng holim'a lebokose la spindle, e ka etsang hore moea o pholile le ho pholisa metsi bakeng sa sesebelisoa le likarolo tsa mosebetsi. Ho hlomelloa ka sethunya sa moea ho hloekisa mochini le likotoana tsa mosebetsi.

6.Pneumatic system

Pneumatic unit e ka sefa litšila le mongobo mohloling oa khase ho qoba tšenyo le khoholeho ea likarolo tsa mochini. Solenoid valve unit e laola lenaneo ka PLC ho etsa bonnete ba hore liketso tsa sesebelisoa sa spindle unclamping, spindle center blowing , spindle clamping tool le spindle air coolant li ka etsoa kapele le ka nepo. Nako le nako ha sesebelisoa sa ho fetola li-spindle, moea o hlakileng o hatelletsoeng o tla foka ho tloha setsing sa spindle ho hloekisa lesoba le ka hare la spindle le shank ea sesebelisoa bakeng sa ho tiea ho hoholo ha motsoako le ho ohla le sesebelisoa. E tla eketsa nako ea bophelo ea spindle.

7.Tshireletso ea mochine

Re sebelisa thebe e tloaelehileng ea tšireletso bakeng sa mochini, e ke keng ea sireletsa feela ho phatloha ho pholileng empa ts'ebetso ea ts'ireletso. Tsela e 'ngoe le e 'ngoe ea tataiso e na le thebe ea tšireletso ho thibela sepholi le sekhechana se sehang sebakeng se ka hare le ho theola sekoahelo le khoholeho ea sekoahelo sa tataiso le screw ea bolo.

8.Lubrication system

Guideway le ball screw li na le sisteme e bohareng ea lubrication hape e na le karohano ea oli ea volumetric sebakeng se seng le se seng, se ka fanang ka oli ka bongata bo tsitsitseng le ka linako ho etsa bonnete ba hore sefahleho se seng le se seng se tlositsoe ebile se theohile. E tla ntlafatsa ho nepahala le nako e telele ea bophelo ba "ball screw and guideway".

9.Chip tsamaiso ea conveyor

Re fana ka sesebelisoa se tloaelehileng sa "chip remover" se sebetsang habonolo. Hape o ka khetha mofuta oa screw type chip conveyor kapa mofuta oa hinge.

| Ntho | Yuniti | VMC640L | Setšoantšo sa VMC640LH | VMC850L | VMC1000L |

| Tafole ea mosebetsi | |||||

| Boholo bo sebetsang | mm | 400×900 | 400×900 | 500×1000 | 500×1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5×18×100 | 5×18×100 |

| Tsamaea | |||||

| X maeto a axis | mm | 640 | 640 | 850 | 1000 |

| Y axis leeto | mm | 400 | 400 | 500 | 500 |

| Z leeto la axis | mm | 400 | 500 | 600 | 600 |

| Mokhahlelo oa mochini | |||||

| Sebaka ho tloha setsing sa spindle ho ea pele likholomong | mm | 440 | 476 | 572 | 572 |

| Sebaka ho tloha qetellong ea spindle ho ea tafoleng ea mosebetsi | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Boemo ba mochini | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Boima ba mochine | |||||

| Max. moroalo oa tafole ea mosebetsi | kg | 350 | 350 | 500 | 600 |

| Boima ba mochine | kg | 3900 | 4100 | 5200 | 5600 |

| Spindle | |||||

| Thepa ea lesoba la spindle | BT40 | BT40 | BT40 | BT40 | |

| Matla a spindle | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. lebelo la spindle | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Fepa(direct drive) | |||||

| Max. lebelo la fepa | Mm/mots | 10000 | 12000 | 12000 | 12000 |

| Lebelo la ho fepa ka potlako (X/Y/Z) | m/m | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Ball screw (diameter + lead) | |||||

| X axis ball screw | 3210 | 3212 | 4016 | 4016 | |

| Y axis ball screw | 3210 | 3212 | 4016 | 4016 | |

| Z axis ball screw | 3210 | 4012 | 4016 | 4016 | |

| Makasine ea Lisebelisoa | |||||

| Bokhoni ba limakasine tsa lisebelisoa | T | 16 | 16 | 24 | 24 |

| Nako ea ho fetola lisebelisoa | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Ho nepahala ha boemo (boemo ba naha) | |||||

| Ho nepahala ha boemo (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Ho nepahala ha maemo (X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| NO. | Lebitso | Brand |

| 1 | Sistimi ea CNC | Seimens 808D SYSTEM |

| 2 | Enjene e ka sehloohong | Sete e felletseng ea Nokia drive ho kenyelletsa servo motor |

| 3 | X/Y/Z axis motor, mokhanni | Seimens |

| 4 | Ballscrew | Hiwin kapa PMI (Taiwan) |

| 5 | Ho beha li-ballscrew | NSK (Japane) |

| 6 | Litataiso tsa linear | Hiwin kapa PMI (Taiwan) |

| 7 | Enjene ea spindle | POSA/ROYAL (Taiwan) |

| 8 | Mocheso oa mocheso | Taipin/Tongfei (Mokhoa o kopanetsoeng) |

| 9 | Likarolo tse kholo tsa sistimi ea lubrication | Proton (khoebo e kopanetsoeng) |

| 10 | Likarolo tse kholo tsa tsamaiso ea moea | AirTAC (Taiwan) |

| 11 | Likarolo tse kholo tsa sistimi ea motlakase | Schneider (Fora) |

| 12 | Pompo ea metsi | China |